The buoyant float with a long term magnet rises or falls along helpful information tube with the rising or falling degrees of the medium being measured. The guideline tube is installed with a reed get in touch with, that is energized by the motion of the magnet. Whenever a preset Liquid level sensor stage is attained, the reed gets in touch with is actuated.

The guide tube’s reed contacts contain contact results in within the hermetically sealed glass body. These move collectively or apart whenever a magnetic industry is used from the float. Whenever a reed contact includes a normally open functionality, the results are brought in to getting in touch with when a magnetic industry is applied. Once the contact between your leaves is manufactured, a present flows through the shut results in and a switching transmission is detected.

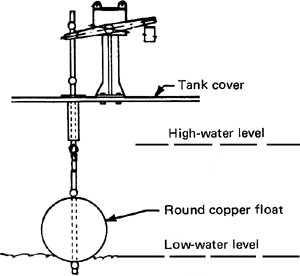

Probably the most reliable, well-proven technology for liquid degree sensing is really a float switch. This kind of change comprises a magnet included within a float, in addition to a magnetic reed change contained inside a fixed casing. The motion of the float, because of the changing liquid degree, may cause the reed change to use (i. e. near or open up ) at a specific degree. This attempted and trusted technology is founded on a comparatively simple design that provides long-lasting reliability with no need for an individual to calibrate the change.

Whilst you can find different methods designed for choosing the right level sensors for a specific application, the key things to consider include the following:

Physical arrangement and style

The decision of styles which may be suited to a credit card application will rely on the physical arrangement of the tank, the available installation positions and whether access can be acquired to the within of the tank. The primary styles are horizontal/ part mounting and vertical mounting. The horizontal/ part mounting type normally includes a fixed casing, which passes through the sidewall of a container, with a hinged float mounted on the fixed casing. Vertical mounting types, as a rule, have a set vertical stem, that is installed through the very best or base of a container, along which slides a cylindrical float.

Another essential consideration is whether an accumulation of deposits from the liquid in the floating body will probably occur. These deposits can, over a period, accumulate to this level that the level sensors can neglect to operate.

Material selection

It is highly recommended to decide on a float switch that’s constructed from the proper materials that are appropriate for the liquids and temperature ranges of this application. Component damage because of this of incorrect materials choice can finally cause failing of level sensors, which might have intense consequences.

Electrical

It is very important to fully understand the type of load that should be switched and make sure that the level of sensors is able to handle this load. The electric ratings, which most producers provide within their float switch specs, are usually for purely resistive loads. Any loads which have either inductive or capacitive elements should have the correct contact protection gauge applied.