In order to ensure the accuracy of laboratory results and the successful conduct of experiments, it is important for laboratory equipment to be both regularly calibrated and to undergo preventive maintenance. Preventive maintenance helps to detect problems early on and reduce their potential effect. It also helps to prevent equipment breakdowns, which can result in costly repairs and unnecessary delays. With regular lab equipment preventive maintenance , laboratory personnel can be assured that their equipment is reliable and accurate enough to yield the best results.

What is Preventive Maintenance?

Preventive maintenance is an inspection and diagnostic process that makes sure equipment is functioning correctly and efficiently. This includes examining the machinery for any potential issues or problems such as worn out parts and components, cracks, leaks, improper connections, etc. Additionally, it is important to check all safety features of the lab equipment and test them for optimal performance.

Why Is Preventive Maintenance Necessary?

Regular preventive maintenance can save your lab from significant downtime due to equipment failure and costly repairs. The goal of preventive maintenance is to make sure the equipment will remain operational at all times, allowing the researchers to continue their work without interruption. It also ensures accuracy in data collection and research results, and prevents any accidents due to unsafe equipment.

How Often Should Preventive Maintenance Be Conducted?

In general, preventive maintenance should be done at least once a year. However, the frequency of maintenance depends on the type of equipment in the lab and how often it is used. Some equipment may require more frequent maintenance while others might only need it every few years.

What Types of Maintenance Are Done?

Preventive maintenance usually consists of regular cleaning, lubrication, adjustment, and calibration. Parts may also be replaced if they are worn, faulty, or need replacing. In some cases, personnel training sessions may be held so staff and researchers know how to properly use the equipment and understand its safety protocols.

Who Is Responsible For Scheduling Preventive Maintenance?

Laboratory technicians and supervisors typically have the responsibility of scheduling preventive maintenance for the lab equipment. Depending on the size of the lab, technicians may even be responsible for doing some of the maintenance themselves. Other maintenance tasks, such as calibration and repair, may need to be outsourced to specialized technicians.

Preventive maintenance is necessary to keep the lab equipment in top shape with maximum performance, accuracy, and safety. By regularly inspecting and maintaining the lab equipment, labs can save time, money, and resources that would otherwise be wasted on repair costs and downtime due to unexpected breakdowns.

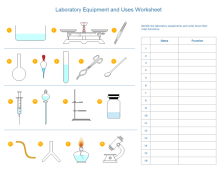

Laboratory equipment is a great tool that helps scientists measure, mix, sort, weigh, and observe the natural world. From microscopes to thermometers, lab equipment is a fundamental part of any scientific research or experiment. In addition to these instruments, there are also safety equipment such as safety goggles and lab coats that help protect scientists when they are conducting their experiments. Laboratory equipment is essential to any laboratory environment and is a vital part of the process of discovering new things in science.